Reduce rail emissions and improve your Rolling Stock

Keeping railways running efficiently and cleanly is essential. HJS UK provides innovative exhaust aftertreatment systems specifically designed for trains and locomotives.

Reduce rail emissions, meet air quality standards, and create a greener future for rail travel. Explore how HJS UK can help your rolling stock breathe easier.

Reduce emissions with innovative technologies for the rail industry

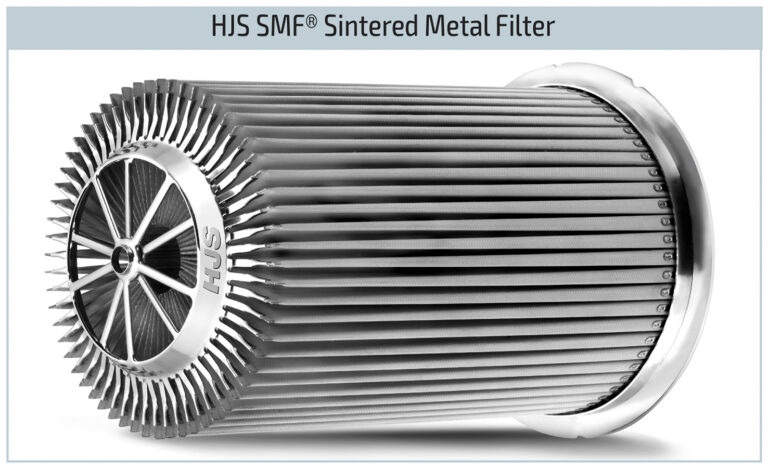

HJS have contributed to air quality improvements reduce emissions in the rail sector for several years providing exhaust systems equipped with its innovative Sintered Metal Filter (SMF®) technology for PM reduction. Due to its unique design, the HJS SMF® has significant advantages in comparison to conventional honeycomb filters in terms of ash loading capacity and cleanability resulting in significantly lower ownership costs over its life time.

The ash loading capacity of an SMF® is approximately 1.8 times higher than a conventional filter which leads to up to 30% more operating hours between cleaning cycles. The SMF® has an open pocket structure allowing access to any ash stored which can then be cleaned using a conventional pressure washer. In summary, the HJS SMF® offers some key advantages when compared to conventional DPF systems.

HJS SCRT technology

The HJS SCRT is a cost effective retrofit exhaust system that can achieve the equivalent of Euro VI emission standards for a diverse range of rail applications. It can be fitted to older rolling stock to provide a cost effective alternative to replacing existing fleet.

The HJS SCRT system combines a diesel particulate filter with an SCR catalyst and AdBlue dosing system for the reduction of Nitrogen Oxides. SCRT is currently the most advanced and effective exhaust gas after-treatment technology available.

Live emission and system performance data can be tracked via the cloud based remote emission monitoring system. The HJS SCRT system has been installed on over 4500 buses throughout the UK, allowing fleet operators to comply with Euro VI emissions standards.

- Upgrade to Stage V emission standards

- Over 99% reduction of Nitrogen Oxides, soot particles (including fine particles)

- Upgrade your fleet rather than replacing it

- Low maintenance and service costs

- Live system performance monitoring via the HJS telematics system

HJS’s modular and bespoke retrofit technologies reduce harmful emissions including PM (Particulate Matter) and Nitrous Oxides (NOx). The HJS SCRT system consists of a DPF and SCR which are combined to provide a simultaneous reduction of PM and NOx enabling operates to upgrade gensets from stage III and IV emissions to meet Stage IV and V Emission Standards.